3D inspection for the first time in fuel cell paste printing

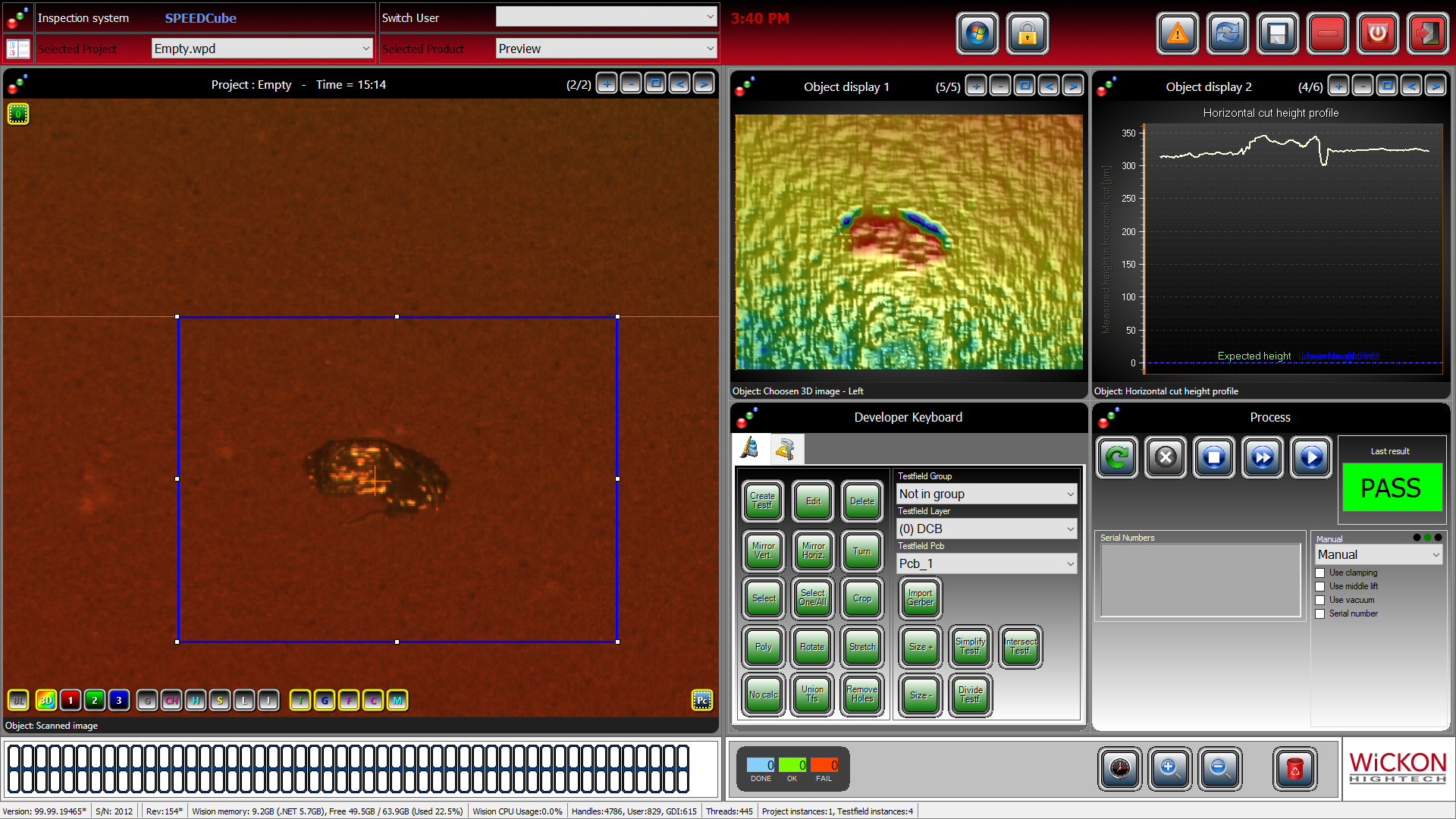

Wickon Hightech has developed an optical inspection system that allows thick film processes in fuel cell production to be inspected in three dimensions in the wet state for the first time. With a dual-track setup, integrable into fast automation lines, the system achieves 3D inspection rates of 2 seconds per track.

Manufacturing fuel cells requires high-temperature MEAs (Membrane Electrode Assembly) and bipolar plates, which are assembled into a stack. For this purpose, layers are applied to ceramic or metal using screen or stencil printing. The printed pastes are necessary for the electrochemical processes or seal the individual layers together by means of a glass seal.

Powerful fuel cells consist of hundreds of MEAs. To meet the requirements of fuel cell manufacturers, fast and reproducible manufacturing processes are necessary – including wet inspection of the freshly printed membranes and IC plates. This is the only way to avoid serial defects and high scrap rates.

Wickon Hightech has developed a fully integrated and functional solution for 3D inspection. The German-Czech provider is able to inspect all common fuel cell paste prints (screen or stencil printing) three-dimensionally – in the wet, dried or sintered state. The technology company has thus succeeded in equipping the world’s first fuel cell production lines with a functional 3D inspection.

To do so, the optical system uses illumination with a numerical aperture that allows wet and wavy surfaces to be detected three-dimensionally. At the same time, both a 3D and a 2D image can be generated in one scan. The high-resolution colour camera unit produces images of 130 x 110 mm in size in 0.6 seconds. Layer thicknesses between 5 and 30 µm can be achieved easily.

Future-proof inspection system: 60 substrates per minute

The fast automation lines in the series production of fuel cell stacks currently achieve cycle rates of up to 15 substrates per minute. Roman Wieser, managing director of Wickon Hightech, says, “Automation manufacturers are aiming to produce at cycle rates of 60 substrates per minute in the near future. Our 3D system will be able to inspect that as well.”

In series productions, the individual process steps are executed sequentially and checked in 2D or 3D using Wickon Hightech technology.

Control 1: Prior to printing incoming inspection for homogeneity, cracks, contamination, warping.

Control 2: Inspection of the wet paste print

Control 3: Inspection of the dried paste print

Control 4: Inspection after sintering process

Interlinked production lines are employed to manufacture MEAs and bipolar plates, which ultimately create a fuel cell consisting of several hundred individual components in one system.

Wickon Hightech’s 3D inspection system can be fully integrated into this manufacturing process. Dimensioning, assembly and installation of the optical elements is handled by Wickon Hightech, including the analysis and automation software as well as the connection to the customer’s network. With a dual track machine and two inspection heads, two tracks run autonomously from each other with an inspection time of 2 seconds per track.

Wickon Hightech is already cooperating with renowned automation companies that deploy their AOI systems. Roman Wieser: “We are part of the development process at an early stage to shape the process landscape.”

Wickon Hightech is a global provider of high-end automated optical inspection (AOI) solutions for industry. Established in 2006, the technology company has succeeded in building a broad range of products and services for optimizing and securing the manufacturing processes of electronic assemblies. The customer focus is on AOI systems in the automotive, renewable energy and medical sectors, e.g. special technical products such as hearing aids with a 3D inspection for wire bonding.

Technical details:

| 2D inspection | 3D inspection | |

|---|---|---|

| Camera resolution | 1,25 µm – 14 µm | 3,5 µm – 12,75 µm (telecentric) |

| Line scan camera (image width in pixels) | 4096 – 16.384 | 4096 – 12.288 |

| Speed | On demand | On demand |

| Inspectable layer thickness | 2 µm – 300 µm | |

| High resolution 3 Sigma | 240 nm |

Press contact

Wickon Hightech s.r.o.

Roman Wieser

Mladoboleslavska 1116

CZ-19700 Prag

+420 602 424 153

roman.wieser@wickon.com

www.wickon.com

AGENTUR PFEIFER

Katja Pfeifer

Ehlersstr. 19

D-81547 München

+49 171 4165721

pfeifer@agenturpfeifer.de

www.agenturpfeifer.de