Inline quality control for MEAs & bipolar plates

3D wet inspection of fuel cells

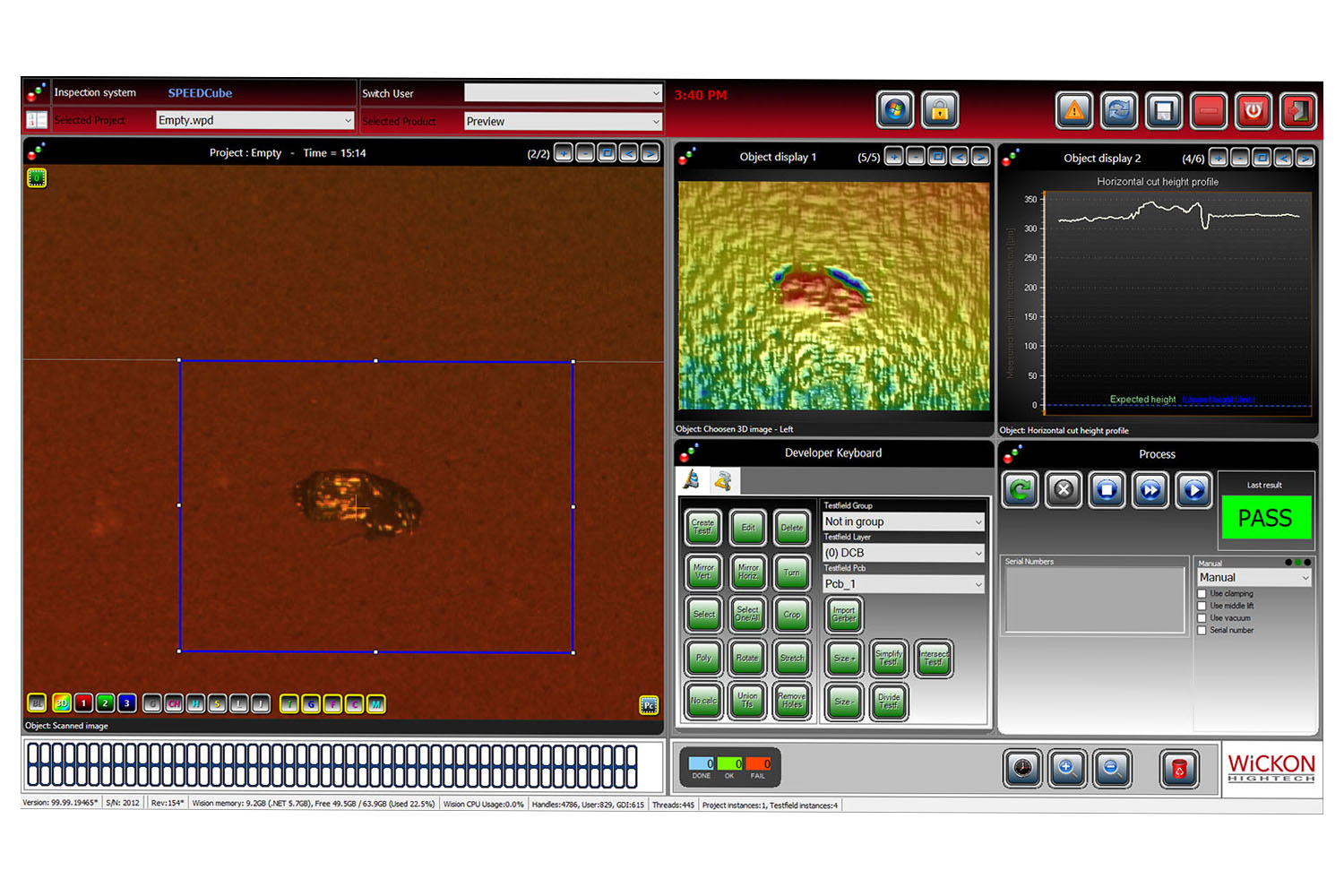

Wickon Hightech has developed an optical inspection system with which thick-film processes in fuel cell production can be inspected three-dimensionally in a wet state for the first time. With a double-track device that can be integrated into fast automation lines, the system achieves 3D inspection rates of 2 seconds/track.

High-temperature MEAs (Membrane Electrode Assembly) and bipolar plates, which are stacked to form a stack, are required for the production of fuel cells. For this purpose, layers are applied to ceramic or metal using screen or stencil printing. The printed pastes are necessary for the electrochemical processes or seal the individual layers together with a glass seal.

Powerful fuel cells consist of hundreds of MEAs. In order to meet the requirements of fuel cell manufacturers, fast and reproducible manufacturing processes are necessary – including wet inspection of the freshly printed membranes and IC plates. This is the only way to avoid series errors and high reject rates.

Wickon Hightech has developed a fully integrated and functional solution for 100% 3D inspection. The German-Czech company can use it to inspect all common fuel cell paste prints (screen or stencil printing) in three dimensions – in wet, dried or sintered condition. The technology forge has thus succeeded in equipping the world’s first fuel cell production lines with functional 3D inspection.

The optical system uses illumination with a numerical aperture that allows wet, wavy surfaces to be detected in three dimensions. Both a 3D and a 2D image can be taken simultaneously in one scan. The high-resolution color camera unit generates 130 x 110 mm images in 0.6 seconds. Layer thicknesses between 5 and

30 µm can be imaged without any problems.

Future-proof inspection system

60 substrates per minute

The fast automation lines for the series production of fuel cell stacks currently achieve cycle rates of up to 15 substrates per minute. Roman Wieser, Managing Director of Wickon Hightech: “The automation manufacturers are aiming to produce at cycle rates of 60 substrates per minute in the near future. Our 3D system will also be able to inspect this.”

In series production, the individual process steps are carried out one after the other and checked in 2D or 3D using Wickon Hightech technology.

- Inspection 1: Before printing, an incoming inspection is carried out to check for homogeneity, cracks, contamination, and warping.

- Check 2: Inspection of the wet paste print

- Check 3: Inspection of the dried paste print

- Control 4: Inspection after the sintering process

Bei der Herstellung von MEAs und Bipolarplatten werden verkettete Produktionslinien verwendet, die am Ende eine Brennstoffzelle erzeugen, die aus mehreren hundert Einzelkomponenten in einem System besteht. Das 3D-Inspektionssystem von WiCKON Hightech ist voll integrierbar in diesen Fertigungsprozess. Dimensionierung, Aufbau und Montage der optischen Elemente wird von Wickon Hightech übernommen, inklusive der Analyse- und Automatisierungssoftware sowie der Anbindung an das Kundennetzwerk. Mit einer Doppel-Track-Maschine und zwei Inspektionsköpfen laufen zwei Tracks autark voneinander mit einer Inspektionszeit von 2 Sekunden pro Track.

WiCKON Hightech arbeitet bereits mit namhaften Automatisierungsunternehmen zusammen und hat dort AOI-Systeme im Einsatz. Roman Wieser: „Wir sind bereits früh Teil des Entwicklungsprozesses, um die Prozesslandschaft mitzugestalten.“

WiCKON Hightech ist ein weltweit tätiges Unternehmen mit High-End-Lösungen zur automatisierten optischen Inspektion (AOI) für die Industrie. Seit der Gründung im Jahr 2006 ist es der Technologieschmiede gelungen, eine breite Produktpalette und Dienstleistungen für die Optimierung und Sicherstellung von Fertigungsprozessen elektronischer Baugruppen aufzubauen. Die Kundenschwerpunkte sind AOI-Systeme im Bereich Automotive, erneuerbare Energien und Medizin, z.B. technische Spezialprodukte wie Hörgeräte mit einer 3D-Inspektion für Wire Bonding.

Technical details

| 2D inspection | 3D-Inspektion | |

|---|---|---|

| Resolution | 1.25 µm - 14 µm | 3.5 µm - 12.75 µm (telecentric) |

| Line scan camera (image width in pixels) | 4096 - 16.384 | 4096 - 12.288 |

| Speed | Upon request | Upon request |

| Inspectable layer thickness | 2 µm - 300 µm | |

| Height resolution 3 sigma | 240 nm |

Press contact

WiCKON Hightech

Roman Wieser

Mladoboleslavska 1116

CZ-19700 Prague

Pfeifer Agency

Katja Pfeifer

Ehlersstr. 19

D-81547 Munich

Press contact

-

WiCKON Hightech

Roman Wieser

Mladoboleslavska 1116

CZ-19700 Prague -

Pfeifer Agency

Katja Pfeifer

Ehlersstr. 19

D-81547 Munich

Are you interested in our hardware, software or services? Are you interested in a product presentation? Write to us – we look forward to hearing from you!