Precise test data in cycle time – for stable processes in your production.

2D & 3D inspection heads for inline quality control

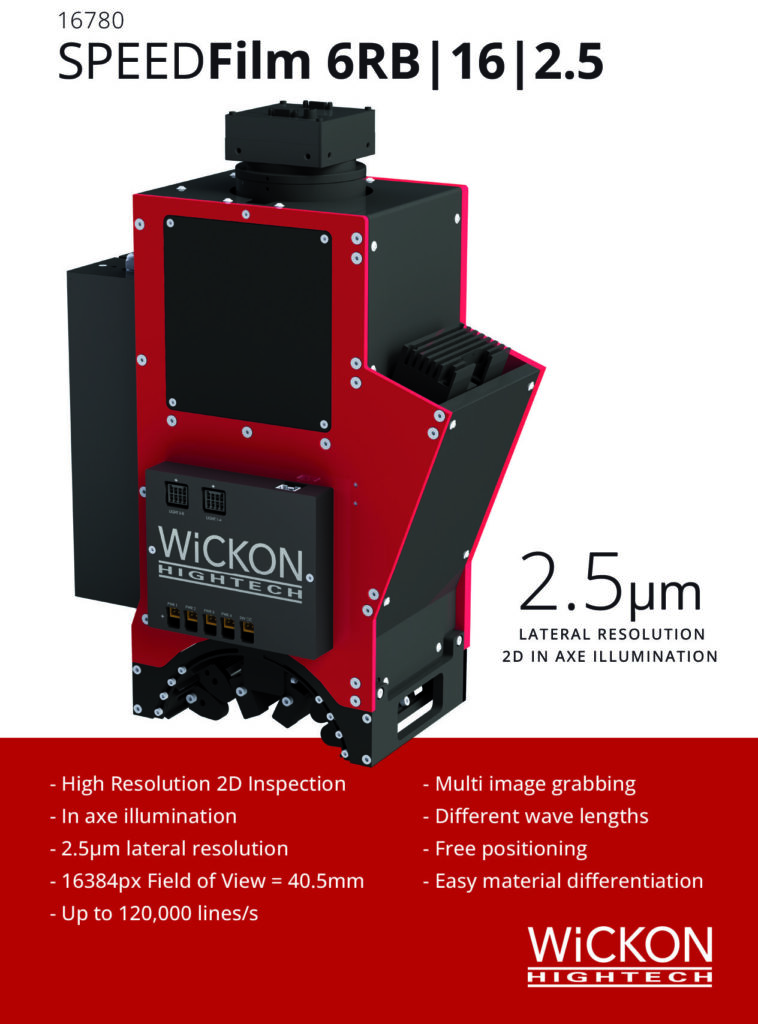

WiCKON Hightech inspection heads deliver highly precise measurement and image data for automated quality control – as a 3D solution for topography, volume, and the smallest height differences, as well as a 2D system for foils, films, and large-area patterns. This allows you to choose the exact technology that suits your process – from SpeedCube, WireBond FBI, and QuantumScan to the 2D system SpeedFilm.

Typical applications

Whether micrometer features or large-area structures – our inspection heads cover a wide spectrum.

From semiconductors and electronics to medical technology, aerospace, energy and military.

Five reasons why WiCKON Hightech inspection heads are convincing in demanding production environments.

High-precision 3D measurement data

True 3D capture for topography, volume and the smallest differences in elevation – as a reliable basis for sound decisions and stable process windows.

2D inspection for films & patterns

Optimized for large-area, mechanically unstable or transparent materials: SpeedFilm delivers fast, reproducible results on foils, films and structured surfaces.

Inline-ready & cycle-time capable

Designed for use in manufacturing: reliable testing processes at high throughputs – for automated quality control directly in the line.

Modular and process-oriented configurable

Industry 4.0 integration (API & standards)

A solution for every problem

2D or 3D - the choice is yours

Which technology is right for your task? The crucial factor is whether you need height information – or whether surface, structure, and pattern are the focus. With WiCKON, you can choose the right inspection technology for your process.

-

3D inspection is ideal when...

Height, volume or layer thickness are process-critical

Topographies, steps, curves or complex geometries must be checked.

Even the smallest defects should be detectable via microstructures or bond geometries.

You need metrological measurement data for process windows, SPC and traceability -

2D inspection is ideal when...

To be tested are foils, films or large-area patterns

Materials are transparent, sensitive, or mechanically unstable

Surface defects such as scratches, particles, inclusions, printing/structural defects must be detected.

You need a fast, reproducible inspection with clear image features

Our systems at a glance

- SpeedCube (3D)

-

SpeedCube – 3D-Inspektion in Taktzeit

Der SpeedCube ist die richtige Wahl, wenn Höhe, Volumen und Topografie prozessentscheidend sind. Das System erfasst Oberflächen und Strukturen als belastbare 3D-Messdaten – ideal für eine Inline-Qualitätskontrolle, die nicht nur „sieht“, sondern wirklich misst. Durch die modulare Auslegung lässt sich der SpeedCube flexibel an unterschiedliche Fertigungsprozesse anpassen – von schnellen Produktionslinien bis zu anspruchsvollen Prüfaufgaben mit hoher Varianz. So entsteht eine stabile Basis für Prozessfenster, Traceability und reproduzierbare Qualität.

- Wirebond FBI (3D)

-

WireBond FBI – 3D-Prüfung für Bond-Qualität und Prozesssicherheit

WireBond FBI wurde für Anwendungen entwickelt, bei denen jede Verbindung zählt. Das 3D-System erfasst Bond-Geometrie und relevante Merkmale so, dass sich Prozessabweichungen früh erkennen lassen – bevor sie zu Ausfällen führen. Gerade in sicherheitskritischen Branchen ist eine robuste, nachvollziehbare Qualitätsprüfung entscheidend. WireBond FBI unterstützt genau das: präzise Messdaten, klare Prüfkriterien und eine Integration, die in moderne Fertigungsabläufe passt. Für Teams, die nicht nur dokumentieren, sondern Prozessstabilität aktiv verbessern wollen.

- QuantumScan (3D)

-

QuantumScan – 3D-Messtechnik mit Nanometer-Präzision

QuantumScan ist für Aufgaben gemacht, bei denen kleinste Höhenunterschiede über Gut oder Ausschuss entscheiden. Das System liefert extrem präzise 3D-Messdaten und eignet sich besonders für Mikrostrukturen und anspruchsvolle Oberflächen, bei denen konventionelle Verfahren an Grenzen stoßen. Ob zur Prozessentwicklung, zur Absicherung kritischer Parameter oder zur Inline-Qualifizierung: QuantumScan bringt die nötige metrologische Aussagekraft – und damit die Sicherheit, Entscheidungen auf belastbare Daten zu stützen. Durch die modulare Konfiguration lässt sich das Setup auf Material, Geometrie und Prozessziel anpassen.

- SpeedFilm (2D)

-

The compact automation cell

The “Mini-Automation-Cell” for magazine-based feeding, automated handling and modular 3D inspection. Can be used stand-alone or inline – to suit your layout.

MacCube – the flexible inline or stand-alone test.

SpeedCube – 3D-Inspektion in Taktzeit

Der SpeedCube ist die richtige Wahl, wenn Höhe, Volumen und Topografie prozessentscheidend sind. Das System erfasst Oberflächen und Strukturen als belastbare 3D-Messdaten – ideal für eine Inline-Qualitätskontrolle, die nicht nur „sieht“, sondern wirklich misst. Durch die modulare Auslegung lässt sich der SpeedCube flexibel an unterschiedliche Fertigungsprozesse anpassen – von schnellen Produktionslinien bis zu anspruchsvollen Prüfaufgaben mit hoher Varianz. So entsteht eine stabile Basis für Prozessfenster, Traceability und reproduzierbare Qualität.

WireBond FBI – 3D-Prüfung für Bond-Qualität und Prozesssicherheit

WireBond FBI wurde für Anwendungen entwickelt, bei denen jede Verbindung zählt. Das 3D-System erfasst Bond-Geometrie und relevante Merkmale so, dass sich Prozessabweichungen früh erkennen lassen – bevor sie zu Ausfällen führen. Gerade in sicherheitskritischen Branchen ist eine robuste, nachvollziehbare Qualitätsprüfung entscheidend. WireBond FBI unterstützt genau das: präzise Messdaten, klare Prüfkriterien und eine Integration, die in moderne Fertigungsabläufe passt. Für Teams, die nicht nur dokumentieren, sondern Prozessstabilität aktiv verbessern wollen.

QuantumScan – 3D-Messtechnik mit Nanometer-Präzision

QuantumScan ist für Aufgaben gemacht, bei denen kleinste Höhenunterschiede über Gut oder Ausschuss entscheiden. Das System liefert extrem präzise 3D-Messdaten und eignet sich besonders für Mikrostrukturen und anspruchsvolle Oberflächen, bei denen konventionelle Verfahren an Grenzen stoßen. Ob zur Prozessentwicklung, zur Absicherung kritischer Parameter oder zur Inline-Qualifizierung: QuantumScan bringt die nötige metrologische Aussagekraft – und damit die Sicherheit, Entscheidungen auf belastbare Daten zu stützen. Durch die modulare Konfiguration lässt sich das Setup auf Material, Geometrie und Prozessziel anpassen.

The compact automation cell

The “Mini-Automation-Cell” for magazine-based feeding, automated handling and modular 3D inspection. Can be used stand-alone or inline – to suit your layout.

MacCube – the flexible inline or stand-alone test.

Download the product flyer as a PDF

Downloads & Datasheets

Here you will find all relevant WiCKON high-tech product flyers as two-page PDFs – ideal for forwarding, printing, or quick team discussions. They contain the most important product information, technical specifications, and typical applications at a glance.

Why WiCKON inspection heads make the difference

More value from every pixel

With WiCKON, you’re not just choosing an inspection head, but a solution that adapts to your process. Our 2D and 3D systems help you detect errors early, reduce scrap, and sustainably stabilize your processes – including software, interfaces, and commissioning expertise. If you briefly describe your inspection task, we’ll recommend the right technology and the optimal setup.

Do you need high-precision AOI inspection heads for 2D or 3D applications? Are you interested in our hardware, software or services? Are you interested in a product presentation? Write to us – we look forward to hearing from you!