Quality in cycle time: precise, fast, scalable

Inline solutions for 2D/3D inspection from WiCKON Hightech

Our inline systems combine high-precision inspection heads , intelligent software , and modular automation into seamlessly integrated quality control solutions – complete inline AOI inspection solutions directly on your production line. Whether ceramics, paste printing, films, or complex assemblies: we ensure consistently high process quality at full line speed.

Why inline 3D inspection with WiCKON?

Inline 3D inspection is strong when precision, cycle time and process knowledge come together. WiCKON combines high-resolution measurement technology with practical application expertise – from projects in the semiconductor industry, medical technology, electronics and energy. This results in solutions that not only find faults, but also make processes measurably more stable: with reproducible results, clear limit values and data that supports decisions in real time. In short: quality assurance that grows with your production.

Modular & flexible

Scalable from a single workstation to a fully automated line.

Safe

2D and 3D inspection combined for maximum process reliability.

Seamless integration

Connection to automation and MES.

Uninterruptible

All our products have a Verify station for removable test parts without a line stop.

Industry 4.0-ready

WiSion platform with real-time analytics and standardized interfaces such as SECS/GEM and OPC UA.

Our systems at a glance

- SpeedCube Inline

-

High-speed 3D

SpeedCube Inline is our central inline system for three-dimensional paste and structure inspection:

- Homogeneity & defect detection for paste applications (e.g. silver sinter paste in e-mobility).

- Chip placement control including rotation, position and height.

- 3D inspection of canals in ceramics – particles, discolorations and defects are reliably detected.

SpeedCube works in inline mode at high speed and with micrometer precision.

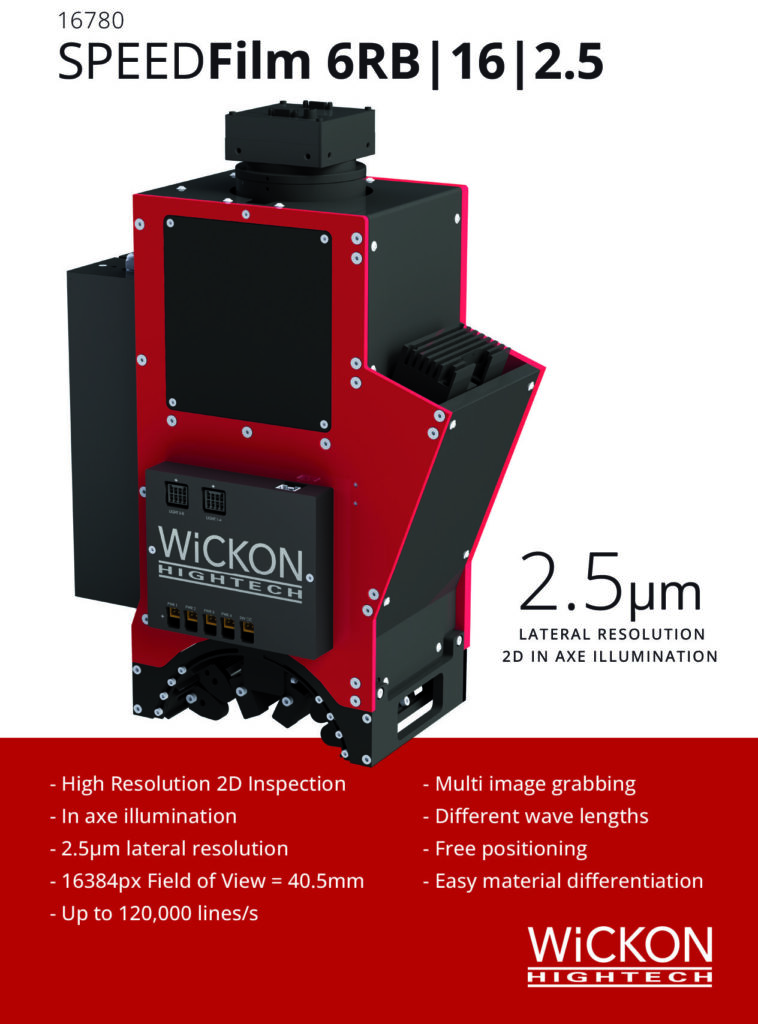

- SpeedFilm Inline

-

Mastering slides with confidence

For large-area, mechanically unstable or transparent films: scanning up to 600 × 500 mm, vacuum table fixing and optional inline or semi-automatic operation – when film quality is crucial to the process.

SpeedFilm Inline ist das bewährte System für Anwendungen, in denen Folienqualität prozessentscheidend ist.

High-speed 3D

SpeedCube Inline is our central inline system for three-dimensional paste and structure inspection:

- Homogeneity & defect detection for paste applications (e.g. silver sinter paste in e-mobility).

- Chip placement control including rotation, position and height.

- 3D inspection of canals in ceramics – particles, discolorations and defects are reliably detected.

SpeedCube works in inline mode at high speed and with micrometer precision.

Mastering slides with confidence

For large-area, mechanically unstable or transparent films: scanning up to 600 × 500 mm, vacuum table fixing and optional inline or semi-automatic operation – when film quality is crucial to the process.

SpeedFilm Inline ist das bewährte System für Anwendungen, in denen Folienqualität prozessentscheidend ist.

Download the product flyer as a PDF

Downloads & Datasheets

Here you will find the compact WiCKON high-tech product flyer as a two-page PDF – ideal for forwarding, printing, or quick team discussions. It contains the most important product information, technical specifications, and typical applications at a glance.

Everything in flux: precision, data, application

Advantages, integration & fields of application

With WiCKON Hightech’s inline 3D inspection, you benefit from complete inline AOI inspection solutions, ensuring quality directly on the production line: intelligent 2D/3D algorithms increase process reliability , reduce scrap, and enable real-time decision-making. Results are seamlessly integrated into your existing systems – standardized via SECS/GEM or OPC UA – and are available on the WiSion platform for analysis, 100% reporting, and complete traceability . This creates a continuous data loop that measurably improves production stability and enables ongoing optimization.

Typical applications range from paste printing and 3D structure inspection to large-area, flexible or transparent films and wirebond inspection. WiCKON also inspects top and bottom sides in throughfeed and records the position, height and rotation of components – inline, on cycle time and reproducible. In short: a scalable solution that combines precision, data integrity and practical benefits – and puts your quality assurance where it matters most: right in the middle of the process.

-

Highest precision

-

Cycle time fixed

-

Industry 4.0-ready

Are you interested in our hardware, software or services? Are you interested in a product presentation? Write to us – we look forward to hearing from you!