Tailor-made for your requirements

3D inspection systems for complex production processes

Standard solutions reach their limits when processes are individual and demanding. WiCKON Hightech develops customized 3D AOI inspection solutions , precisely tailored to your manufacturing requirements – from electronics and energy to medical technology and the semiconductor industry. Our specialized solutions combine state-of-the-art sensor technology, modular mechanics, and intelligent software for maximum precision at full line speed.

What sets our customized 3D inspection systems apart

Our customized 3D AOI inspection systems are not compromises, but rather complete solutions precisely tailored to your production. Hardware and software work seamlessly together, transforming raw data into reliable quality decisions in real time – stable, scalable, and industrially robust. The result: maximum precision at full cycle time and a data flow that measurably increases the efficiency of your processes.

Modular architecture

Scalable platform: optics, lighting, mechanics and software modules are combined to fit perfectly. This results in customized 3D inspection systems that optimally cover component size, process speed and resolution – from the laboratory to series production.

Multi-image & hybrid 2D/3D technology

Precision optics & lighting

Proprietary telecentric optics (1.25-12.5 µm) and multi-wavelength LEDs (450-660 nm). Optional 3D illumination with measuring ranges of 0.125-2.0 mm – ideal for micro-assemblies, transparent adhesive joints or reflective surfaces.

Mechanics & Integration

Customized mechanical modules – from individual guides to retrofitting complete lines. Whether OEM integration or stand-alone cell: WiCKON supplies customized 3D inspection systems that fit seamlessly into your automation.

WiSion intelligent software platform

WiSion connects all hardware modules, processes gigabyte data sets in seconds (< 40 s for 46 GB images) and offers full Industry 4.0 connectivity via SECS/GEM and OPC UA. AI/ML filters reliably detect errors and minimize false calls.

Real-time capable inline performance

100% inline inspection at industrial cycle times: Immediate error reports and reactions in real time – even at high throughput rates.

Our systems at a glance

- Widemus

-

The multifunctional test cell

Combines three technologies in one cell: 3D SpeedCube height measurement, wire bond inspection (FBI) and top/bottom inspection in throughfeed. Ideal for spot welds, pins, component layers, transparent adhesives and ceramic plates. Integrated vacuum grippers ensure reproducible processes.

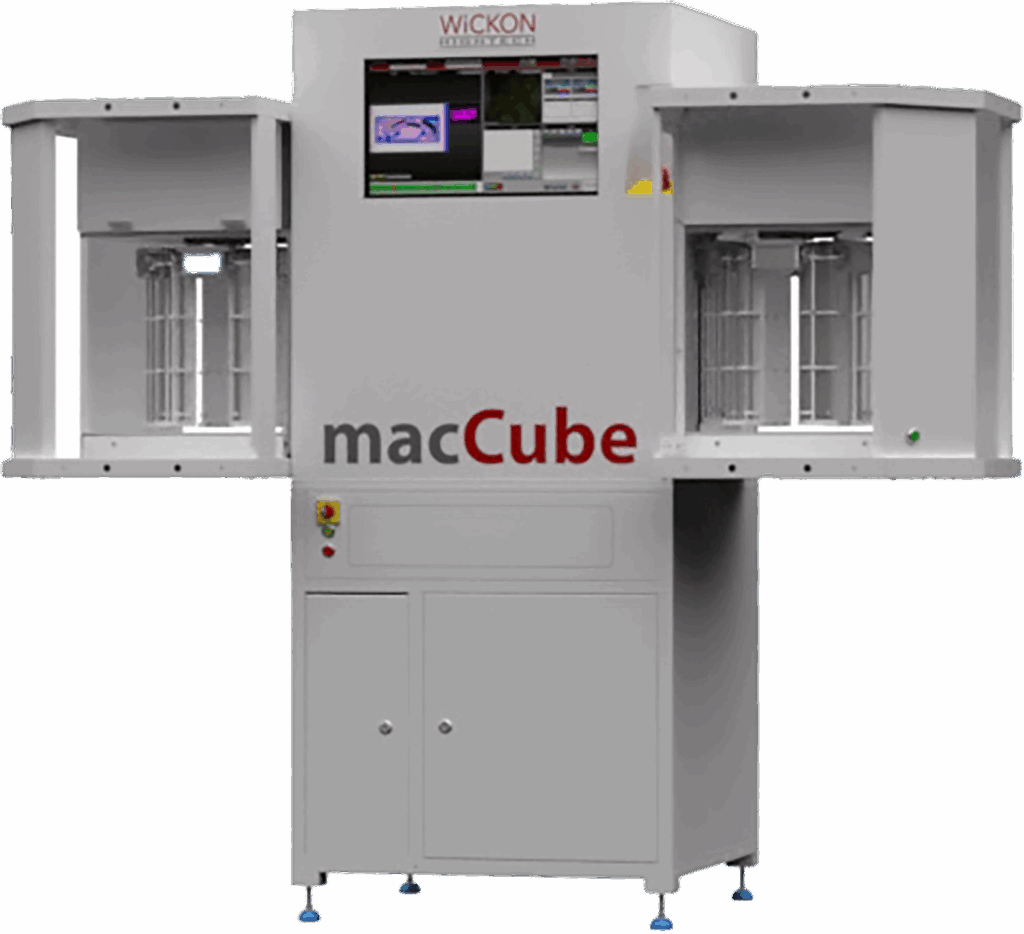

- MacCube

-

The compact automation cell

The “mini automation cell” for magazine-based feeding, automated handling , and modular 3D inspection . Can be used as a standalone or inline solution – entirely according to your requirements.

MacCube – the flexible test solution for inline or standalone systems.

- FBI

-

3D wire bond inspection for maximum detection accuracy

WiCKON Hightech FBI (Fast Bonding Inspection) is a high-precision 3D wire bond inspection system for reliable quality control in the wire bonding process. With complete wire detection, 4.5 µm lateral resolution, and a 73.5 mm field of view, it detects even the smallest deviations – as a standalone, integrated, or customized solution .

The multifunctional test cell

Combines three technologies in one cell: 3D SpeedCube height measurement, wire bond inspection (FBI) and top/bottom inspection in throughfeed. Ideal for spot welds, pins, component layers, transparent adhesives and ceramic plates. Integrated vacuum grippers ensure reproducible processes.

The compact automation cell

The “mini automation cell” for magazine-based feeding, automated handling , and modular 3D inspection . Can be used as a standalone or inline solution – entirely according to your requirements.

MacCube – the flexible test solution for inline or standalone systems.

3D wire bond inspection for maximum detection accuracy

WiCKON Hightech FBI (Fast Bonding Inspection) is a high-precision 3D wire bond inspection system for reliable quality control in the wire bonding process. With complete wire detection, 4.5 µm lateral resolution, and a 73.5 mm field of view, it detects even the smallest deviations – as a standalone, integrated, or customized solution .

From the sensor to the ERP

Integration & data flow - everything in the process

All results flow into your system landscape in real time – standardized via SECS/GEM or OPC UA – and are available in WiSion for SPC, 100% reports and traceability. This creates a closed quality data cycle that makes your production measurably more stable and efficient.

-

Customized 2D/3D precision

-

Inline real-time inspection

-

Industry 4.0 integration

Proven in practice in key industries

Verified fields of application

WiCKON Hightech’s customized 3D inspection systems prove their worth not only in the laboratory, but also in real-world production environments. Across multiple industries, they deliver stable measurement results, are fully inline-capable, and integrate seamlessly into existing automation systems. The following examples demonstrate how precision, cycle time, and data integrity can be reliably combined in demanding processes.

Fuel cell production

First 3D wet inspection in paste printing – inline, 15 µm resolution, 2 s cycle. Layer thicknesses of 5-30 µm are precisely recorded; serial defects detected immediately. → The world’s first line with fully integrated 3D wet inspection.

3D wire bond control (medical technology)

Inline AOI for 18-300 µm wires, 3.2 µm repeatability in z-direction, telecentric 4.5 µm optics. Control of loop height, geometry and waist shape.

Semiconductors & Electronics

3D inspection of pastes, sealing structures and solder. Coded white light technology provides real height maps with > 90 % valid data points – without point clouds, without reconstruction.

Flexible & transparent materials

Inline detection of transparent sealants, films and glasses. Multi-wavelength illumination and adaptive HDR make microscopic height deviations visible.

More precision. More speed. More value.

Your advantages at a glance

Our customized 3D AOI inspection systems directly contribute to product quality, cycle time stability, and cost-effectiveness. You receive clearly interpretable results in real time, reduce waste and create the basis for sound decisions – from prototype to series production. Below you will find a concise overview of the specific advantages your product line gains as a result and how WiCKON permanently strengthens your quality process.

-

Customized 3D inspection systems and AOI

-

Validated, reconstruction-free 3D data

-

Full inline capability with industrial cycle time

-

High data integrity & traceability

-

Modular design for maximum flexibility

-

AI-supported evaluation & process monitoring

-

Smooth integration in OEM and retrofit scenarios

Co-engineering with WiCKON

Future-proof - from the idea to series production

Our customized 3D inspection systems are developed in close cooperation with our customers – from the initial concept to series production. WiCKON Hightech is a partner of well-known automation manufacturers and supports development projects in fuel cells, medical technology, automotive, semiconductors and energy.

Download the product flyer as a PDF

Downloads & Datasheets

Here you will find the compact WiCKON high-tech product flyer as a two-page PDF – ideal for forwarding, printing, or quick team discussions. It contains the most important product information, technical specifications, and typical applications at a glance.

Request your special solution now

Whether it’s individual optics, new sensor technology, tailor-made 3D AOI inspection solutions or a complete inline solution – WiCKON Hightech develops what you really need: precision in the middle of the process.